WOODFLOW TECHNOLOGY

AT A GLANCE

Take one minute to understand why we think Woodflow will disrupt lightweight construction and help diverse industries to move towards a more sustainable future.

RESTORING WOOD’S

INTELLIGENCE

In nature, trees are high-performance structures. They withstand amazing wind and snow stresses just by having the right form, density, and fiber orientation.

We have developed a design-to-manufacturing technology that brings this natural intelligence back to engineered structures.

Body and interior parts for sustainable mobility

We aim to provide electromobility companies of the future with the chassis, seats and body parts that will make them a truly sustainable transportation alternative.

Body and interior parts for sustainable mobility

We aim to provide electromobility companies of the future with the chassis, seats and body parts that will make them a truly sustainable transportation alternative.

UNLOCKING THE POWER OF NATURAL WOOD

Our design-to-manufacturing technology aims to bring the natural intelligence of tree structures to engineered wood. We combine digital design, structural optimization and digital fabrication to produce structural wood-based composite parts.

OUR TECHNOLOGY

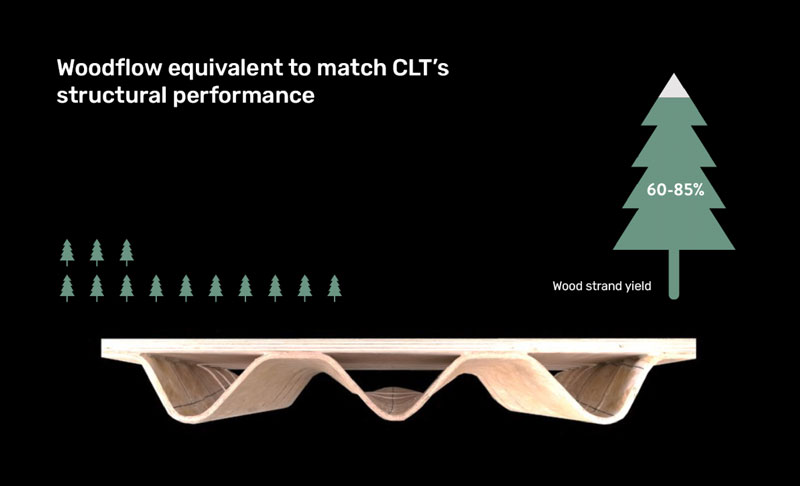

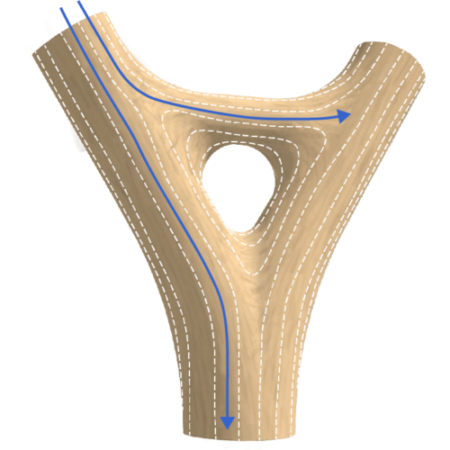

Woodflow technology enables the use of wood-based composites for lightweight high-performance applications. The right control over the form and material architecture allows us to produce stress-tailored structural parts capable of fully profiting from wood’s performance. For example, our 34.8 kg lightweight slab prototype could withstand 630 kg (beyond Eurocode 5 requirements for residential structures) with a deflection of only 6.2 mm.

WOODFLOW TECHNOLOGY

Our design-to-manufacturing computational platform allows us a fully automated process from design to fabrication.

This level of control over the form and fiber orientation of our composite parts enables us to achieve maximum performance with minimum material.

SOFTWARE + ADDITIVE MANUFACTURING

Our proprietary software enables us to integrate computational design, structural optimization, and fabrication in a seamless process.

Additionally, our additive manufacturing technology allows for the placement of the wood composite with the right density, fiber orientation and thickness that the component requires. This allows us to tailor the component’s mechanical performance to unprecedented levels.

WHY WOODFLOW?

– is high-performance and sustainable

– it uses wood strands, that make more efficient use of the forestry resource

– because is additive manufacturing-based, its production generates minimum waste

– optimized parts by form and fiber orientation employ minimum amounts of material

– its freeform capabilities allow us to solve complex geometries and fuse several functions into one part, reducing assembly times and chances of failure

– its automated design-to-manufacturing process delivers consistent quality and high-productivity

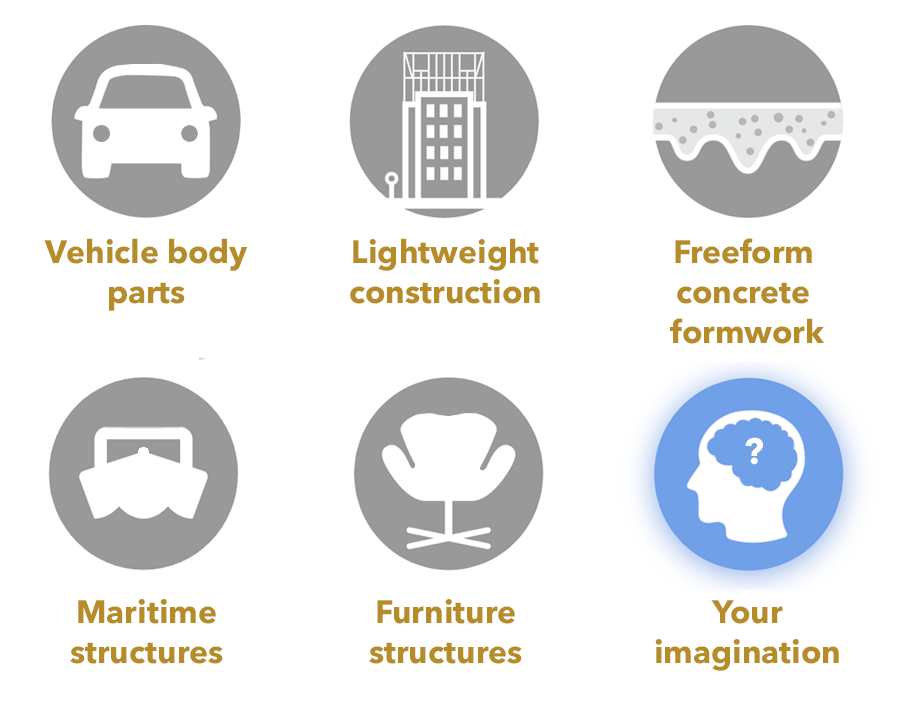

ONE TECHNOLOGY,

MANY APPLICATIONS

OUR TEAM

A committed team with the competencies and experience needed to realize this challenge.

CEO

Andrés Mitnik Asun

Civil Engineer UC, MPA

Int.I Development, Harvard

Master in Urban Planning, NYU

Technology Innovation

Manager, Fundación Chile

CTO

Daniel Ortiz del Río

Architect, MArch UC

Founder of two Digital Fabrication Companies

Digital Fabrication advisor

CPO

Jorge Christie Remy-Maillet

Architect, MArch UC

MSc. ITECH Stuttgart University

MAS Digital Fabrication ETH Zurich

Dipl. in Business Administration

KUKA Certified Robot Programmer

NEWS

© Copyright 2024 WOODFLOW TECHNOLOGIES S.L. – All Rights Reserved